testing sealed electric motors|electric motor voltage test : Brand DOE finalized key provisions related to small electric motor testing in a 2009 final rule at 74 FR 32059 (July 7, 2009), . An “electric motor with sealed windings” is defined as an electric motor engineered to pass the conformance test for water resistance as specified in NEMA MG1-2009.

Chicken legs: 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Citizen trousers: 0 0 0 0 0 0 +2 +2 0 0 0 0 0 0 Zamorak robe legs: 0 0 0 +4 0 0 0 0 +4 0 0 0 0 +5 Mime legs: 0 0 0 0 0 0 0 0 0 0 0 0 0 0 .

{plog:ftitle_list}

Resultado da If you have Telegram, you can view and join Trans365 right away. 😍 TRANS ARCHIVES - АРХИВ ТРАНСОВ 😍 Добро пожаловать ️ Download .

In this comprehensive tutorial, we unveil the secrets to effectively testing any motor using a multimeter. Whether you're a DIY enthusiast or a professional electrician, mastering standard.Testing of single phase motors is pretty easy if certain basic steps are followed. The objective of any AC motor test is to determine the health status of the motor. The basic steps in ascertaining the health of any motor are given below. (a) .2.2 MIL-STD-2037, Procedure to Obtain Certification for Electric Motor Sealed Insulation Systems 2.3 Equipment Technical Manual 2.4 9086-DA-STM-010-/CH-100, Hull Structures 2.5 S9086-KC-STM-010/CH-300, Electric Plant - General 2.6 S9086-KE-STM-010/CH-302, Electric Motors and Controllers

electrical designs are backed by a 5-year warranty. Easy to install From oversized conduit boxes, lead separators, . other joints are sealed with RTV type sealant for added protection against . Documented final motor test – ships with motor Epoxy paint system exceeds 300+ hour salt fog test per ASTMB117 Other IEEE 841 Fault Diagnostic Testing. Troubleshooting tests are one of the most important tests for assessing a motor’s troubleshooting capabilities. These tests are designed to simulate common fault situations to assess whether the . DOE finalized key provisions related to small electric motor testing in a 2009 final rule at 74 FR 32059 (July 7, 2009), . An “electric motor with sealed windings” is defined as an electric motor engineered to pass the conformance test for water resistance as specified in NEMA MG1-2009. Follow these practices to maximize electric-motor performance and longevity. By Mark Barnes, PhD, CMRP, Des-Case Corp. Treated correctly, electric motors can last a long, long time. In many cases, motors fail prematurely not because of any design, manufacturing, or installation issues, but from the most fundamental of root causes: poor lubrication.

To have an efficient electric motor running means more than just adequate performance; energy efficiency, operating cost, life span, and system reliability are all interconnected with overall motor health. To keep these variables in check, regular motor testing and monitoring are critical. Even basic diagnostic testing can allow for major.

testing a single phase electric motor

Regardless of the application, it’s a good practice to always test rotation. If a 3-phase motor rotates in the wrong direction, you can swap any two leads to change to the desired direction. One way to test motor direction is to take your best guess on how to connect the leads, then run the motor and note the direction it spins.Electric motor with sealed windings means an electric motor capable of passing the conformance test for water resistance described in NEMA MG 1-2016, . For purposes of 10 CFR part 431 and EPCA, the test procedures for measuring the energy efficiency of an electric motor shall be the test procedures specified in appendix B to this subpart B.Electric Motor Testing Methods You Need to Know: Production Processes Measurement of electric motors’ winding resistance. It’s possible to check for wiring breaks by measuring the resistance of motor windings. If these measurements are made using a high-precision resistance meter, manufacturers can also detect errors in wire thickness and .Best Practices for Using Grease for Bearing Lubrication. The best way to reduce your need for electric motor service is to protect the bearings of your electric motors, and one of the easiest ways to do this is to make sure that the bearings for that motor are always adequately lubricated. Most electric motor bearings use grease for lubrication (although some use .

Next week I will have the opportunity to see a sealed winding conformance test (per NEMA MG-1 section 20.18) on one of our newly-rewound 13.2kv motors. The motor stator will be thoroughly wetted with water (including a wetting agent like detergent), and then will have ac voltage of 115% of line-to-line voltage applied line to ground applied.

how to test electric motors

There is some disagreement among electric motor manufacturers as to the best bearing arrangement for horizontal-type, grease-lubricated, ball bearing motors. . Although it has been claimed that sealed ball bearings in electric motors will survive as long as bearing operating temperatures remained below 150°C (302°F) and speed factors DN (mm .Our MotorSafe stripping method carefully removes the original windings to initiate the electric motor rewind process. This method ensures that the core iron and mechanical characteristics remain intact without any damage to their integrity. We use computerized machines to wind all coils, ensuring uniformity and accuracy, and employ Class H wire, phase insulation, and other .

For form-coil windings, conduct a PI test in addition to the IR test. The PI test variables skew results for windings with lots of exposed conductor surface area, so use the DA ratio test for random windings and DC armatures (Tables 1 and 2). If the windings need to be cleaned and dried, measure the IR again.

Important role of enclosure. The enclosure of the motor must protect the windings, bearings, and other mechanical parts from moisture, chemicals, mechanical damage and abrasion from grit. NEMA standards MG1 . Electrical Motor Testing Maintenance. Friday, August 5, . Life Extension of sealed bearings in Electric Motors. Read more. Using a "Megger" as a predictive tool. Tuesday, March 31, 2020 . improving Electric Motor Reliability and Energy Savings are immediate. 3Phi Reliability Sarl 3Phi Reliability, LaTerrasse 19510 Meilhards FR.

%PDF-1.6 %âãÏÓ 867 0 obj > endobj 879 0 obj >/Filter/FlateDecode/ID[7816B8ABEAD3B844B9002096A54A1F64>]/Index[867 32]/Info 866 0 R/Length 77/Prev 759281/Root 868 0 .1 to 1.5 NLGI grades in this test. An electric motor bearing grease that softens more than that may leak out of the bearing with age. Grease Compatibility With some exceptions, greases with different types of . others, those being open or single shielded or sealed bearings, should be re-lubricated periodically to replace grease that has . How to test a sealed lead acid battery? To test a sealed lead acid battery, use a multimeter to measure its voltage. Ensure it’s fully charged and rested. Set the multimeter to DC voltage mode, then place the probes on the battery terminals. Readings below 12.6 volts may indicate the battery needs charging or replacing.

Adhesive Tape Tester inc

Let's tear down an electric motor! This video is a walkthrough of a hands-on lab activity for a summer skilled trades exploration course at Laney College in .Adding Grease to Electric Motor Bearings Re-greasing Intervals Electric motors utilizing double shielded or double sealed bearings, which are typically of the lubricated-for-life design, usually do not require regreasing. On the other hand, all others, those being open or single shielded or sealed bearings, should be re-lubricated

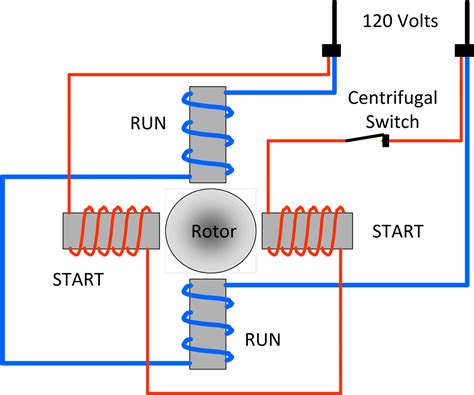

Study with Quizlet and memorize flashcards containing terms like 1. Motors that are not hermetically sealed use a ____ switch to disconnect the start windings from the circuit. a. magnetic b. rotation c. hermetic d. centrifugal, 2. The direction of rotation for a split-phase motor is determined by the direction of rotation of the magnetic field created by the run and start .A test bench for electric motors is a testing system for the reproducible testing of mechanical and electrical properties, the thermal design, overload capacity and other application-specific measurands on electrical drives. The Importance of Electric Motor Testing. Electric motor testing is critical to ensuring the machines we depend on are reliable, efficient, and safe. These tests — conducted throughout the stages of an electric motor’s life cycle — provide essential information about the motor’s overall health and provide designers, manufacturers .

electrical testing for HVAC compressor motors At an applied voltage of 500V, this IRT reading shows >550 MΩ, indicating resistance is out of range. A second IR . But this standard is for motors that are not her-metically sealed with oil and refrigerant. A motor submersed in liquid may need to use lower values as recommended by the .Occasional Duty Electric Motors: Motor runs less than 2 hours per day: 5 years: Intermittent Duty Electric Motors: Motor runs 2-12 hours per day: 2 years: Continuous Duty Electric Motors: Motor runs 12 or more hours per day: Annually: Permanently-lubricated Electric Motors: No oil ports, factory-sealed pre-lubricated bearings: Never A wye-connected motor with an open winding will test differently from a delta-connected motor. An open single-circuit winding will be “single-phased“. Its power will drop to about half, and the motor won’t start. If the motor’s internal connection is multicircuit, it will start but will have reduced power.

Initial Adhesion Tester inc

how to check electric motors

Resultado da Imobiliária Cardinali - São Carlos, SP (16) - Lecto. Imobiliária Cardinali está na Lecto, disponibilizando os dados de telefones, endereços, .

testing sealed electric motors|electric motor voltage test